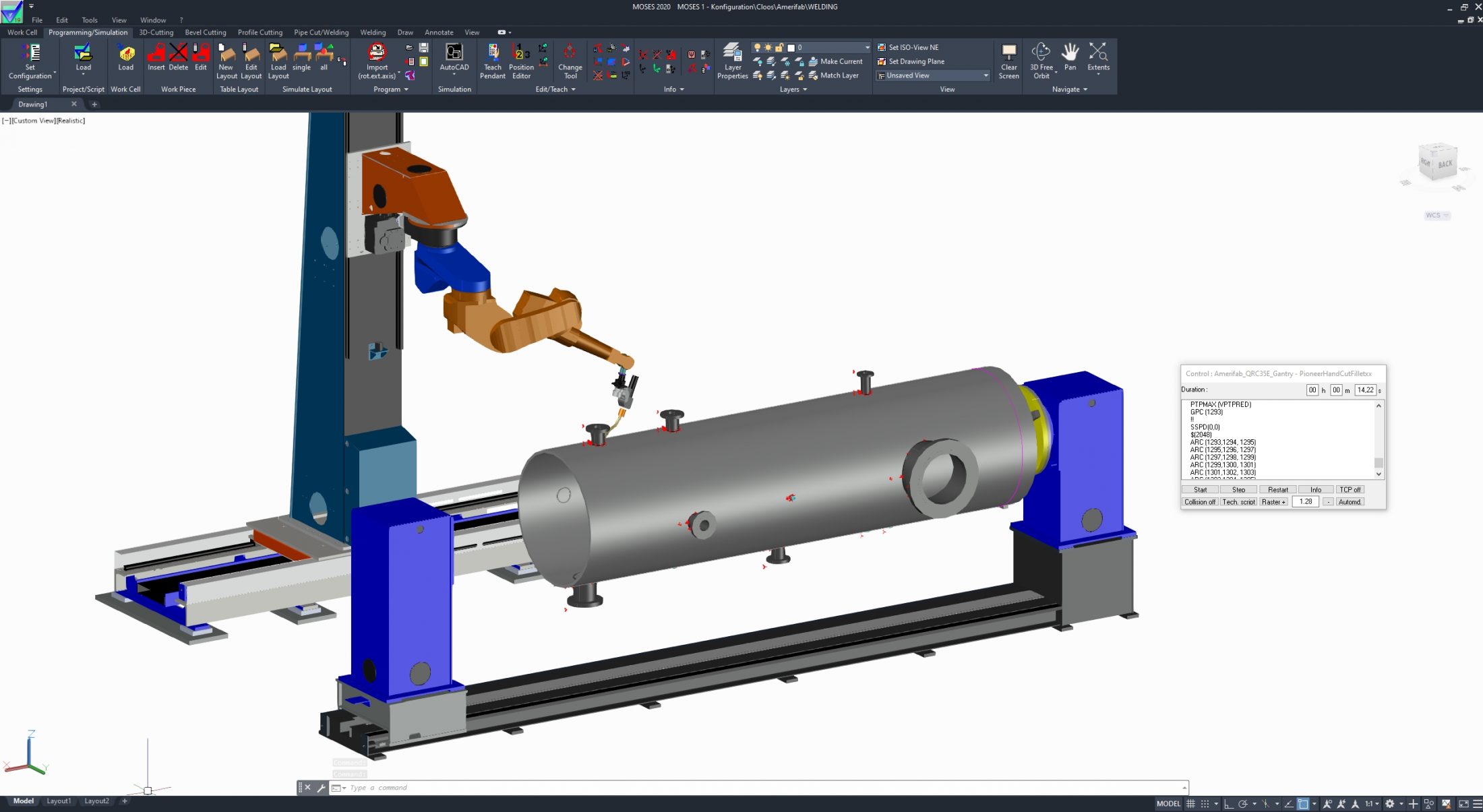

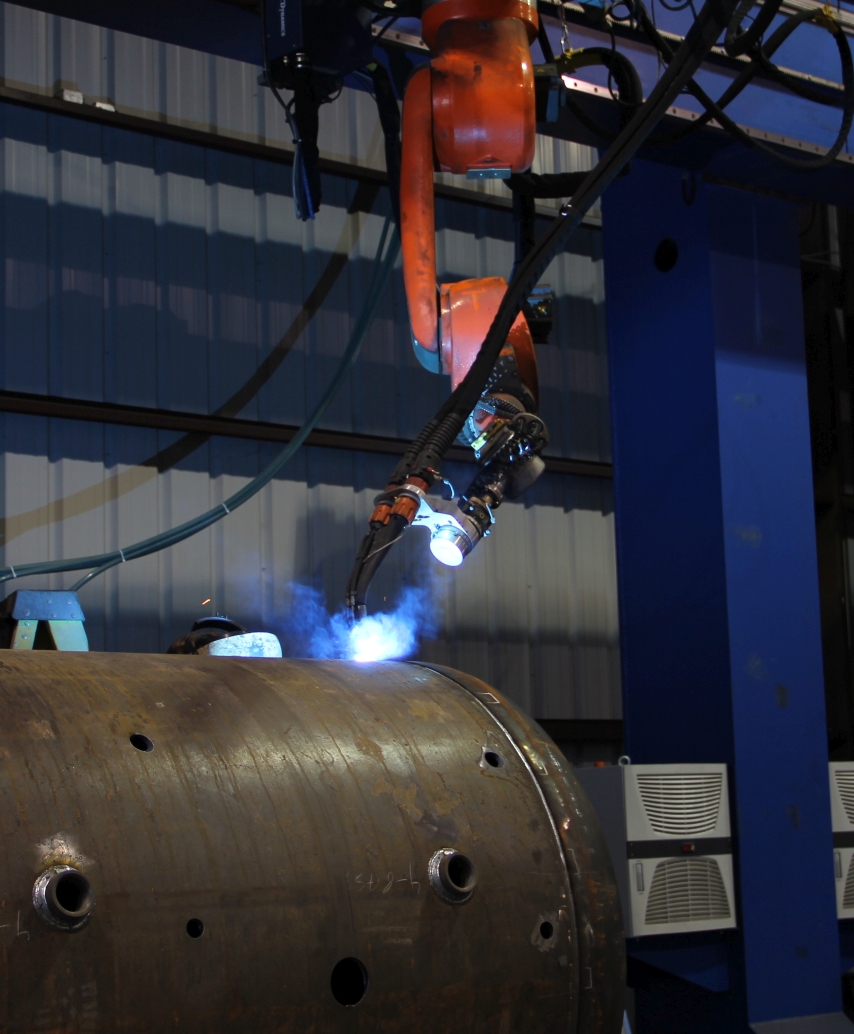

This module is the ideal tool if you want to create robot programs for welding in nozzles in pipes or vessels quickly and easily offline. If you have already created the cutting programs with our Modul MOSES Pipe CUT module in the first work step, of course this information can be used to define the welding task and only a few parameters need to be added. Of course, you can also use MOSES Pipe ARC if the holes have not been cut with our software.

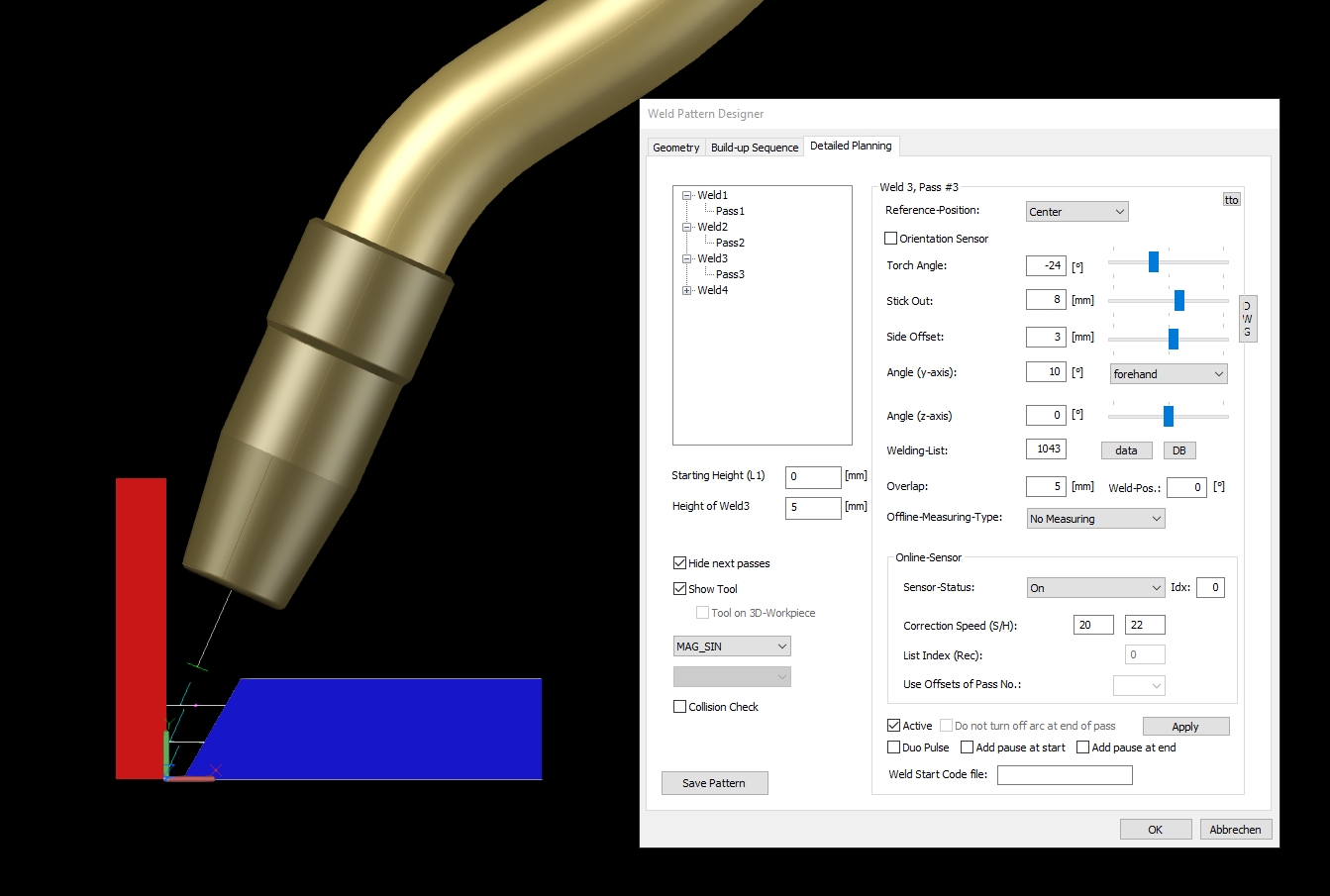

For a good welding result, the weld layer pattern plays a central role. For a user-friendly definition of these weld templates, we have implemented a weld pattern designer. This tool generates patterns for HV welds and fillet welds. All relevant informations are stored and can be assigned to the nozzle by selecting the welding pattern.

Of course, the welding pattern includes intelligent management of determined offset data, which can be recorded by an arc sensor. These values can be imported for subsequent layers where the use of the sensor is not stable due to geometric boundary conditions.

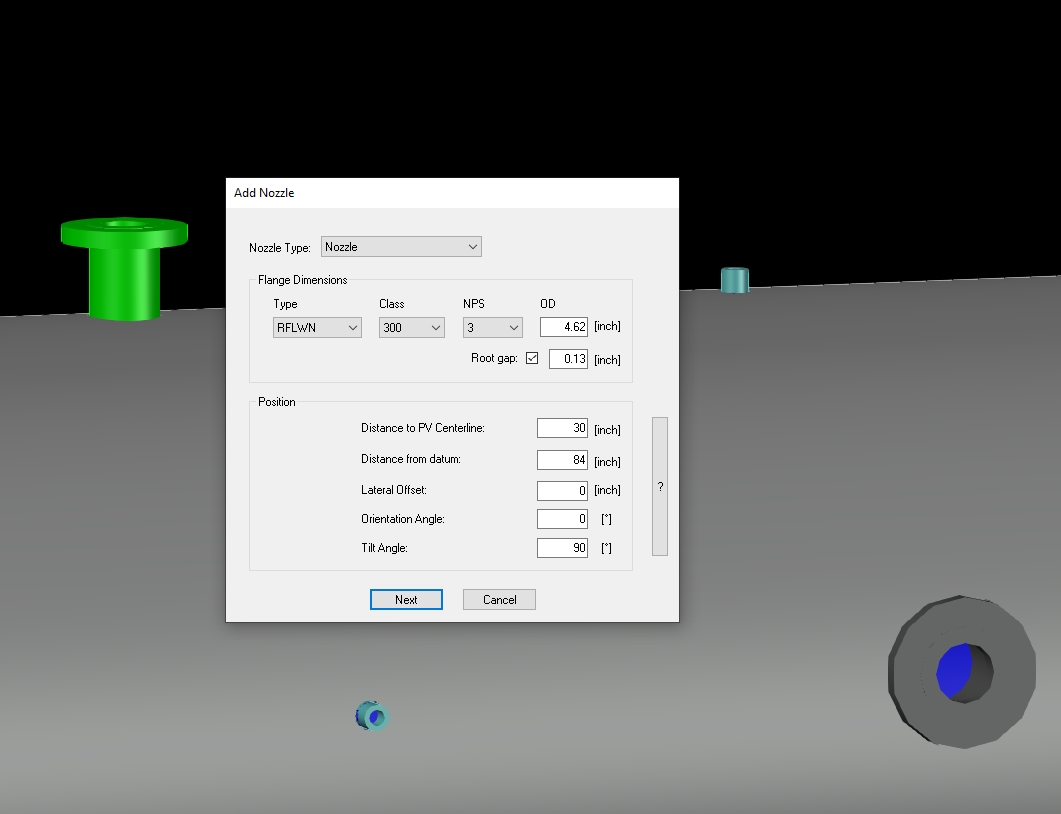

For a collision-free simulation of the welding program, it is important that the data of the flange are known when creating the program.

For this purpose, the operator has access to a database containing all common flanges. These are inserted into the CAD model. This ensures that the automatically generated approach movements are collision-free.

With MOSES Pipe ARC, heads can also be welded to the shell. Here, the weld pattern additionally includes the welding position of each individual layer when using a synchronous rotary positioner.