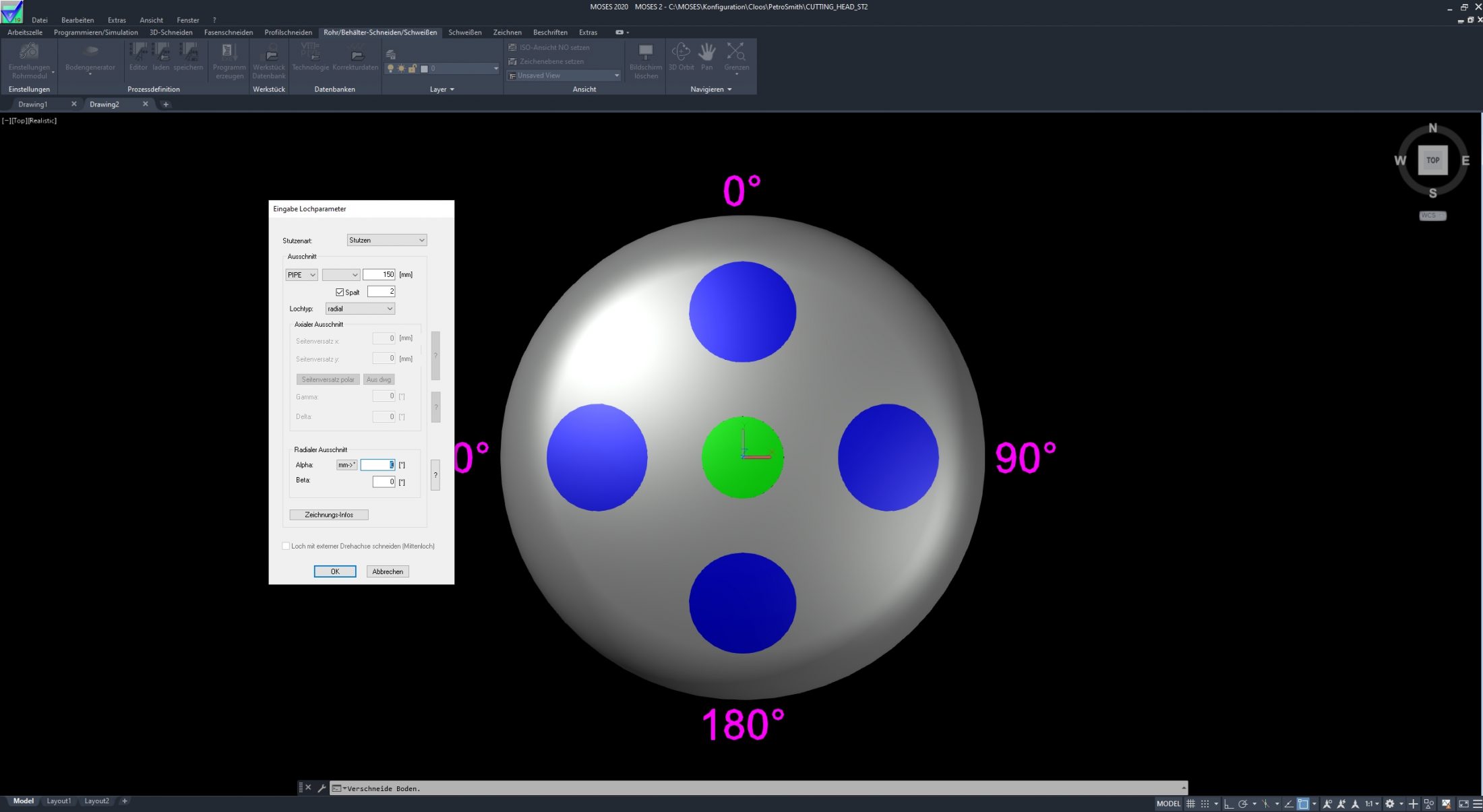

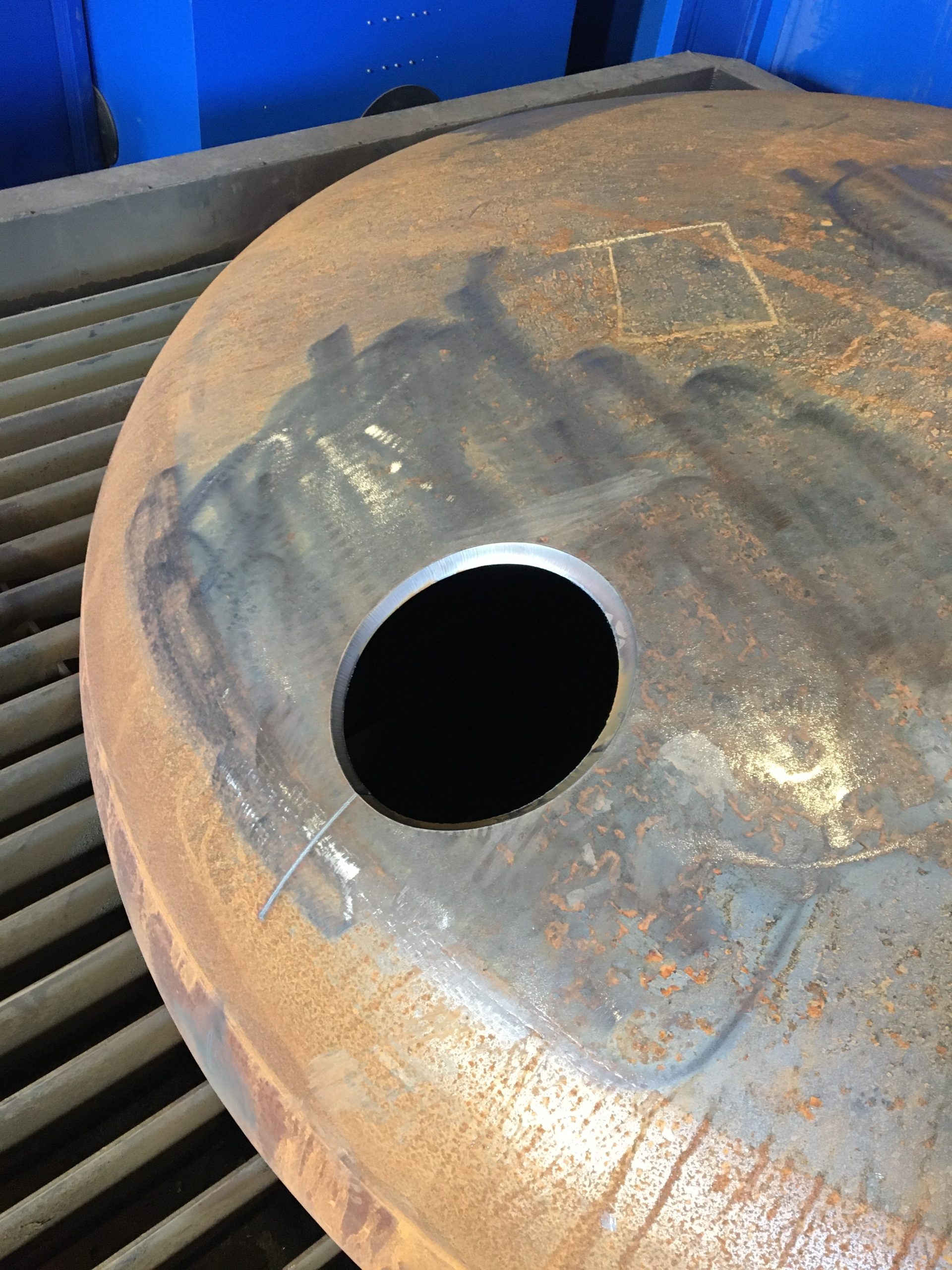

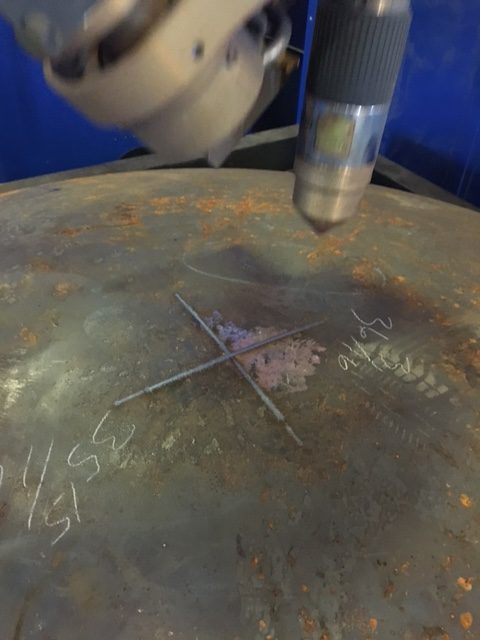

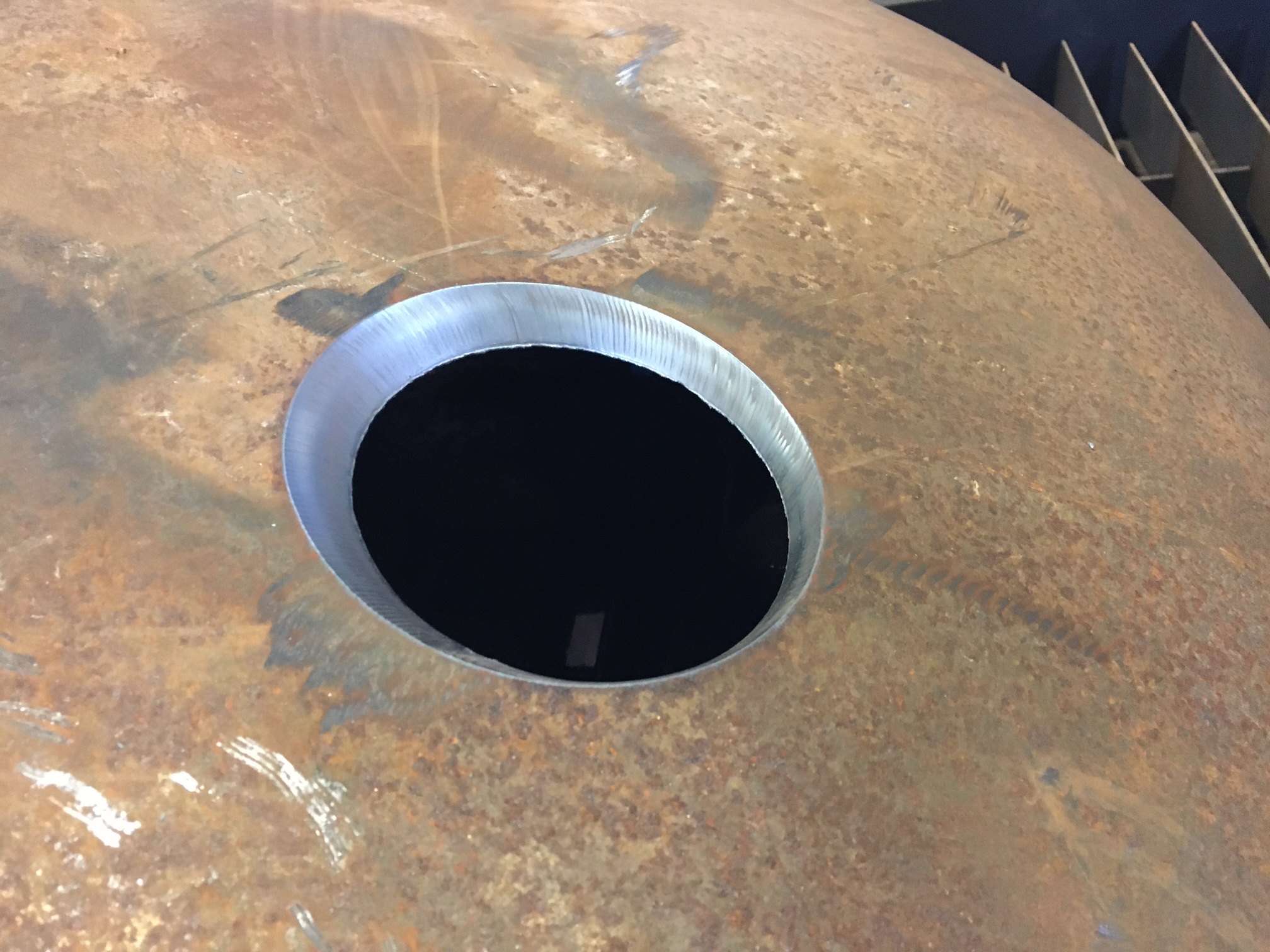

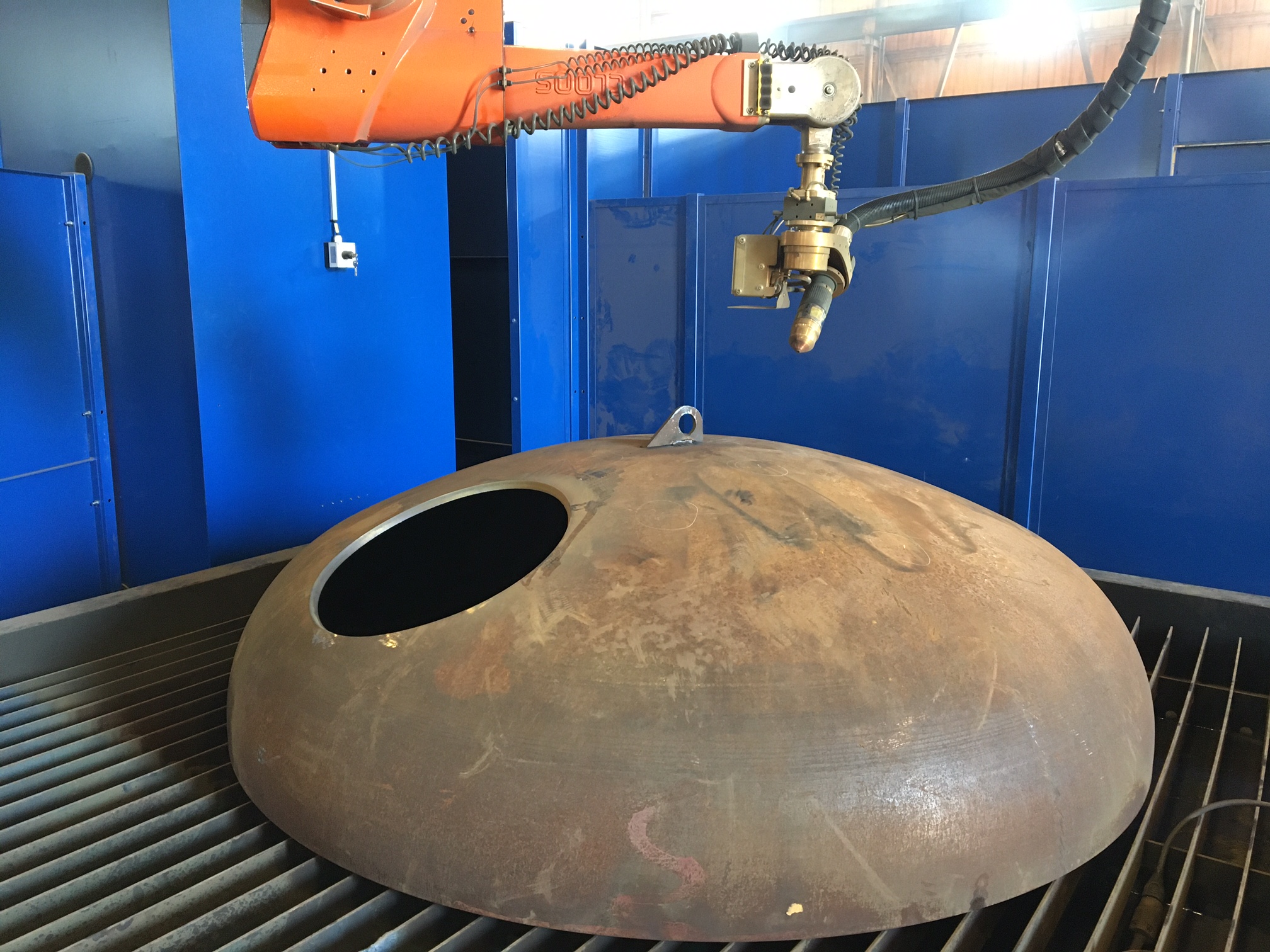

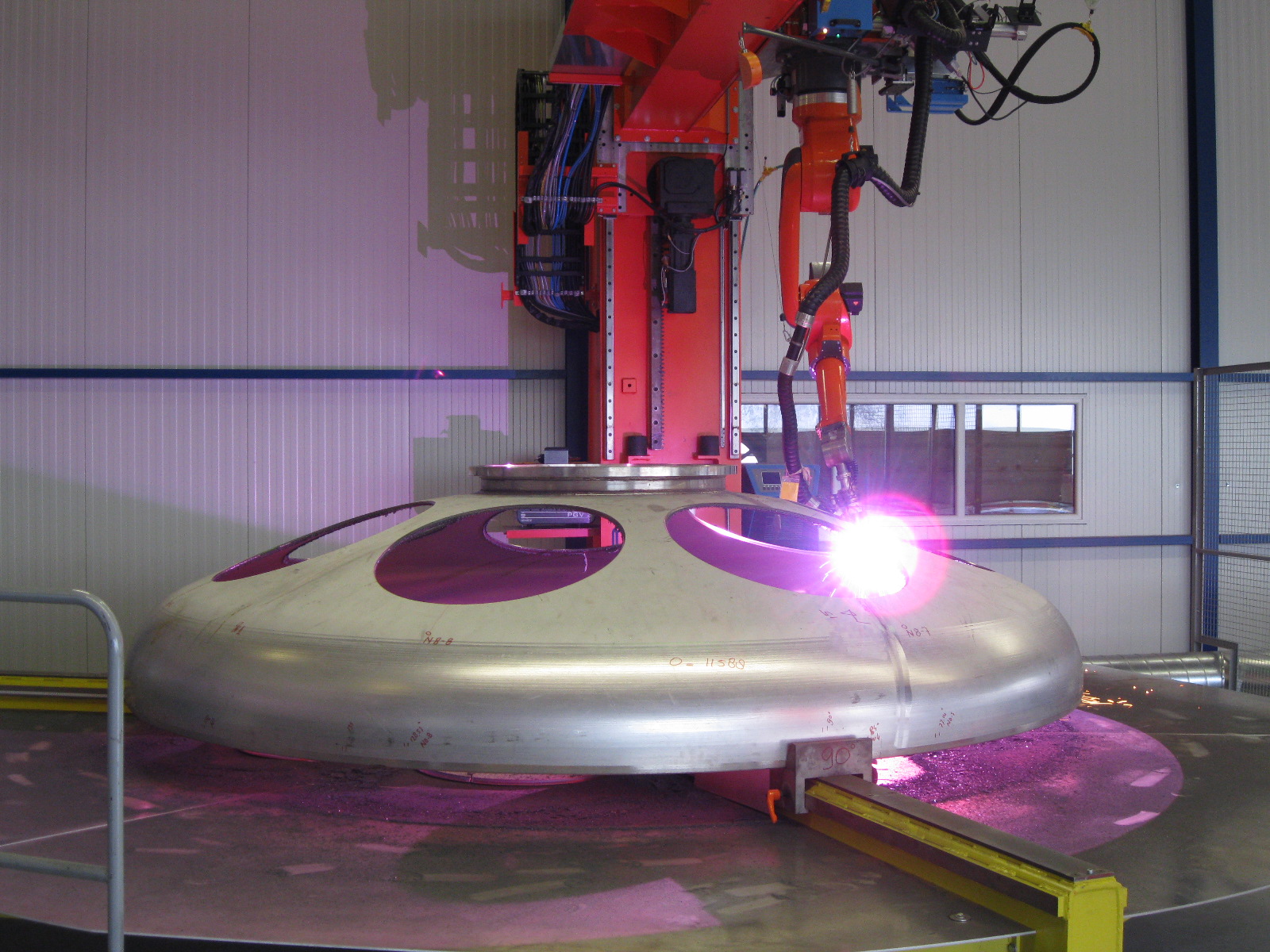

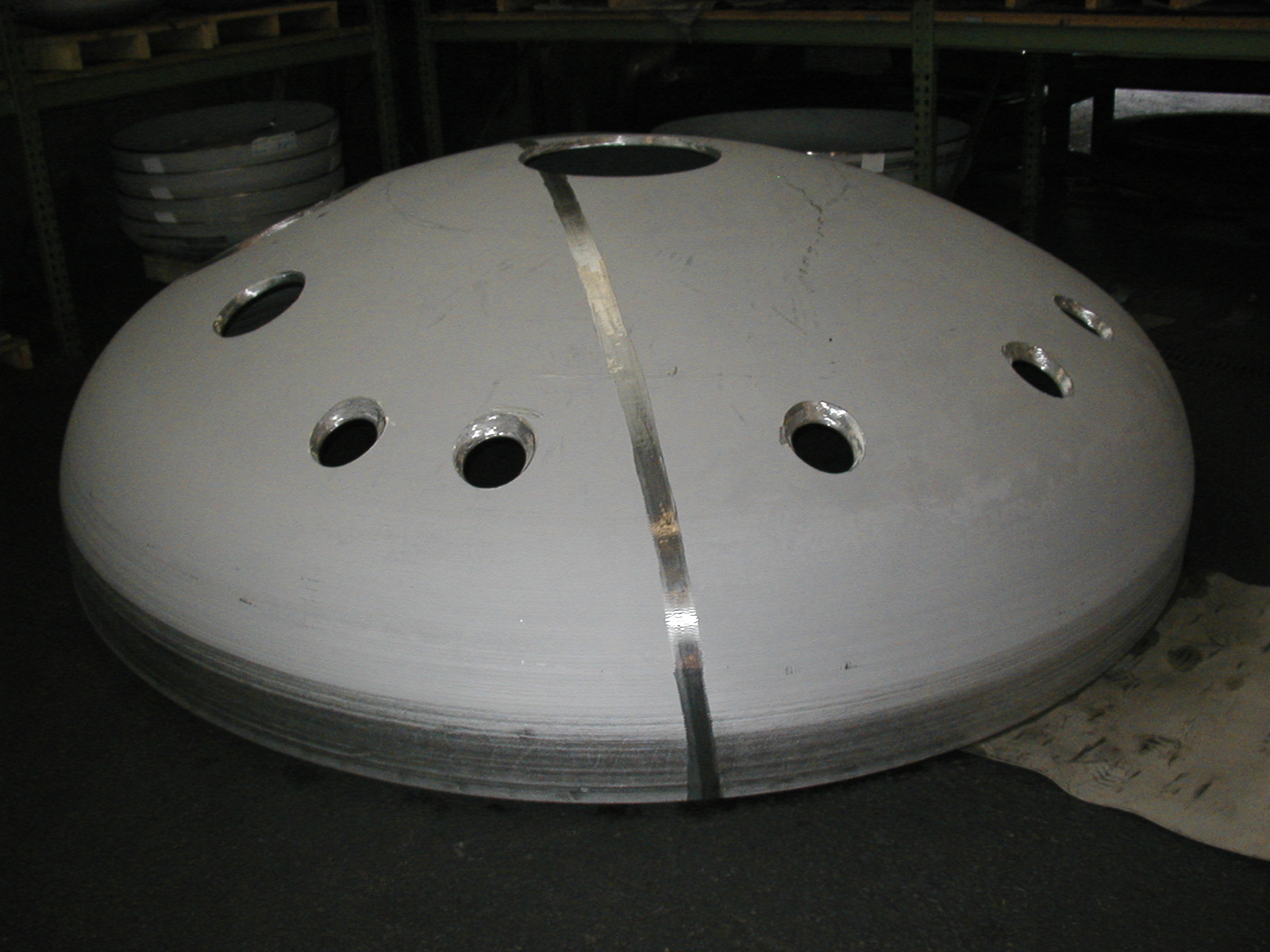

For the machining of heads for vessels and tanks, we have developed the MOSES Head CUT module. The main applications here is the cutting of cutouts, the marking of attachments and the welding in of nozzles (MOSES Head ARC). Like all other modules, data input is reduced to a minimum. First, the operator selects the head type and specifies the geometrically relevant parameters. All common types (torisspherical , semi ellipsoidal, elliptical, hemispherical, dished, flat, convex disk, plate-type, diffuser heads) are available here. Next, the nozzle holes are positioned and oriented (axial or radial). Then the programmer chooses the shape of the weld edge preparation. Once the input is complete, a robot program is generated fully automatically out of this information. This not only contains the cutting (marking) of the head, but also all relevant measuring programs. Heads can have quite large shape tolerances. It is therefore necessary to scan contours before cutting and to convert the deviation from the CAD contour to the cutting contour. Of course, the real position of the head is also compensated by a suitable measuring strategy.

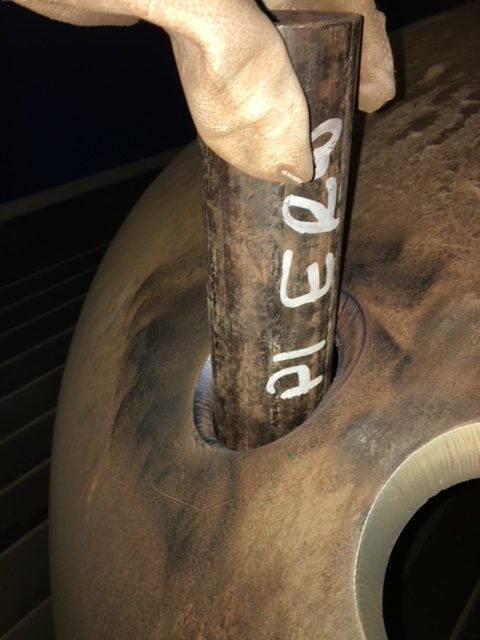

In a further step, robot programs for welding in the nozzles can be generated with the module MOSES Head ARC.