The powerful tool for the automated generation of chamfer cuts

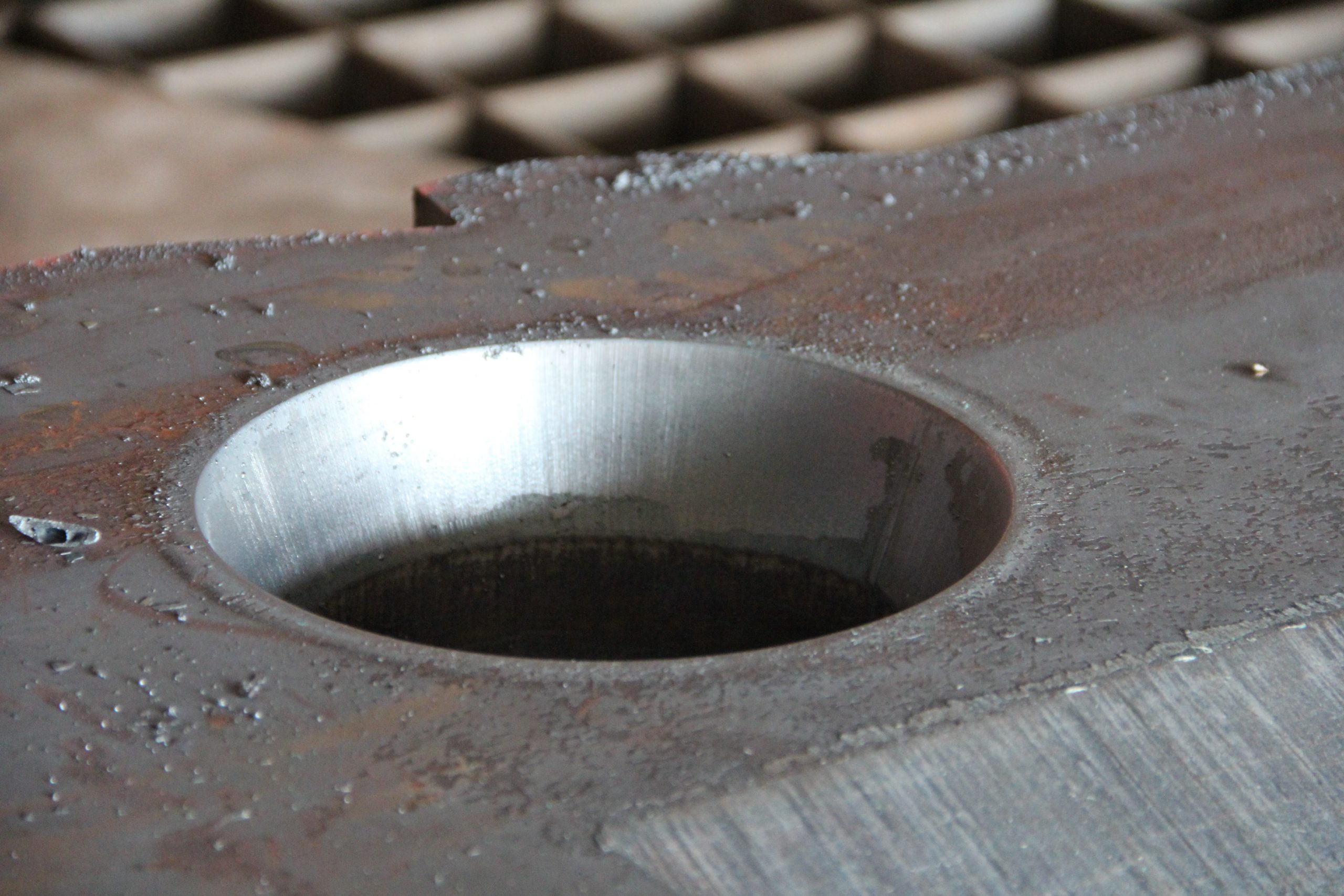

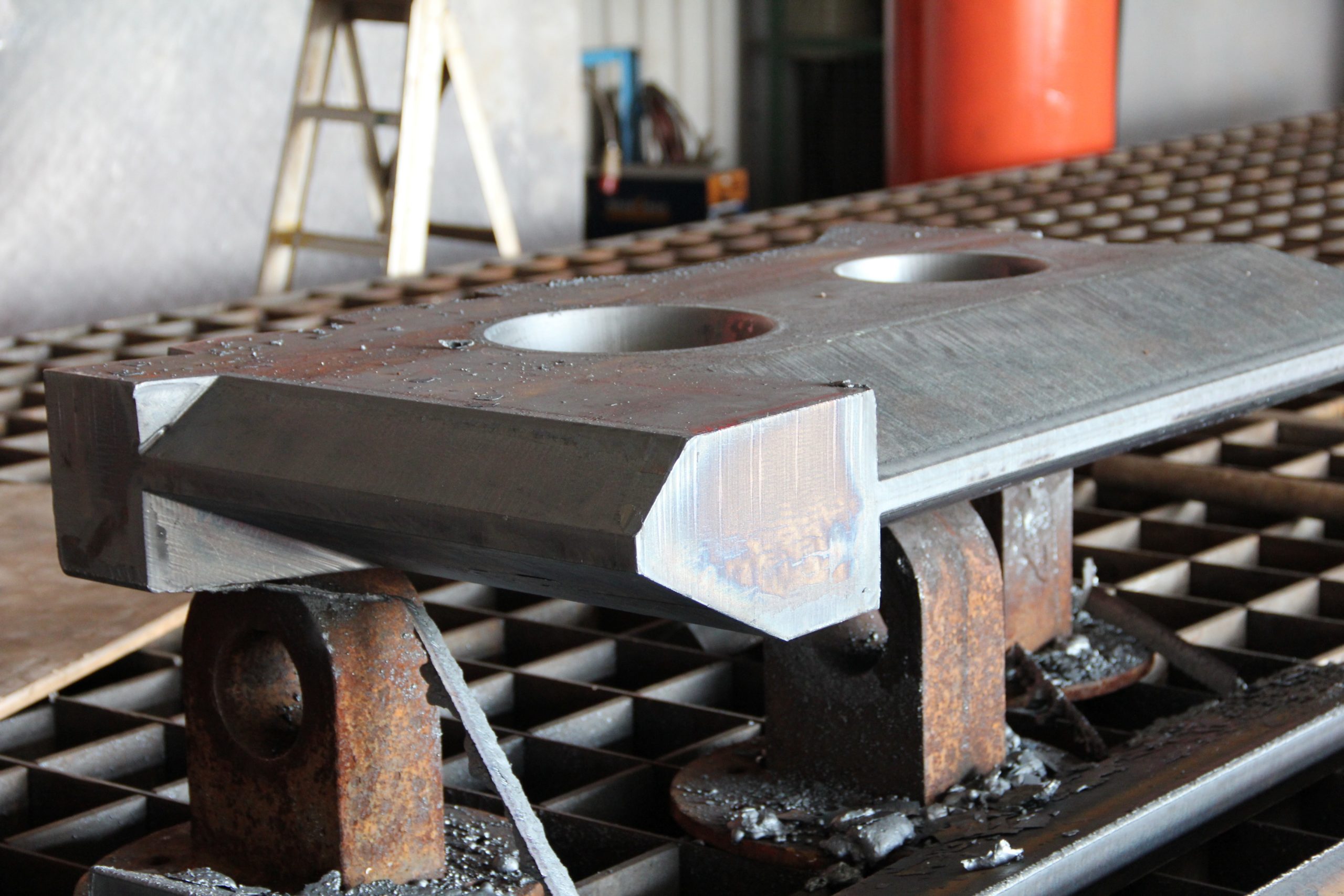

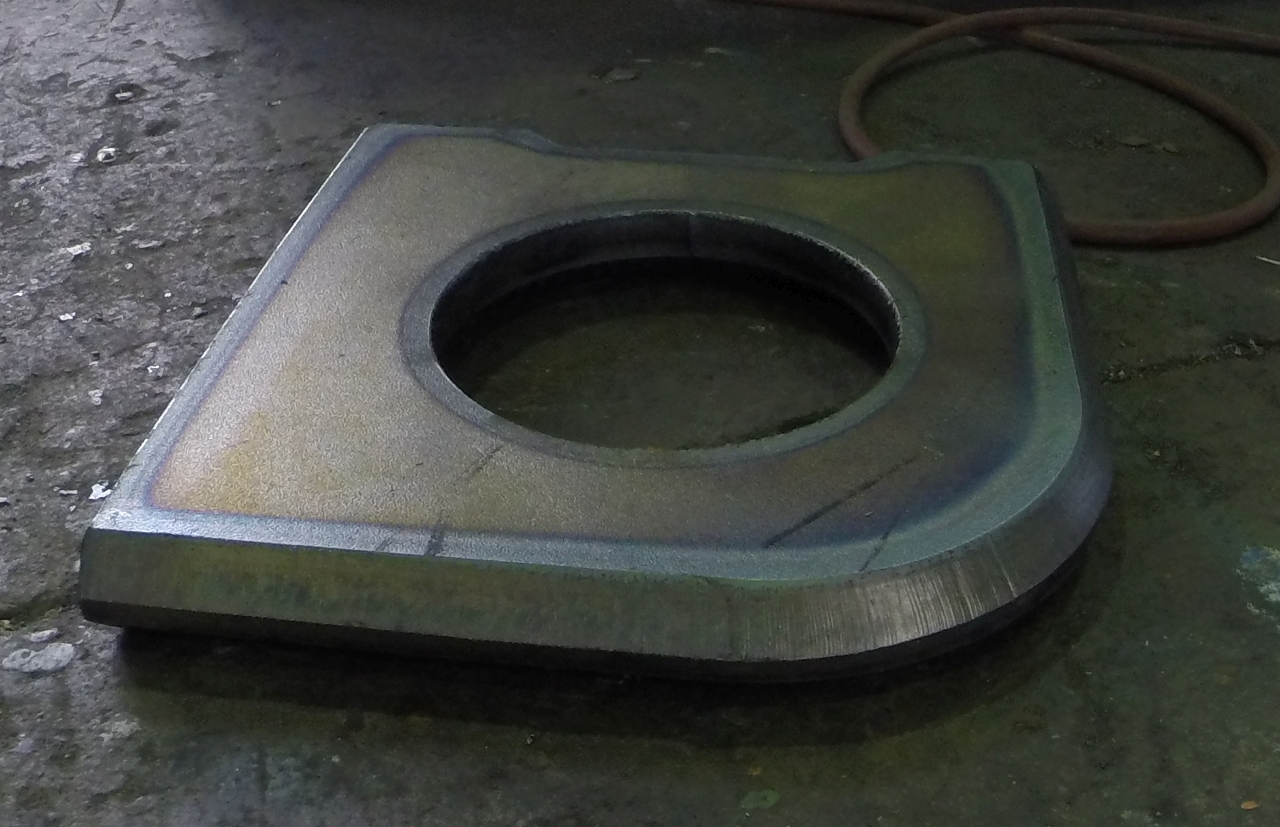

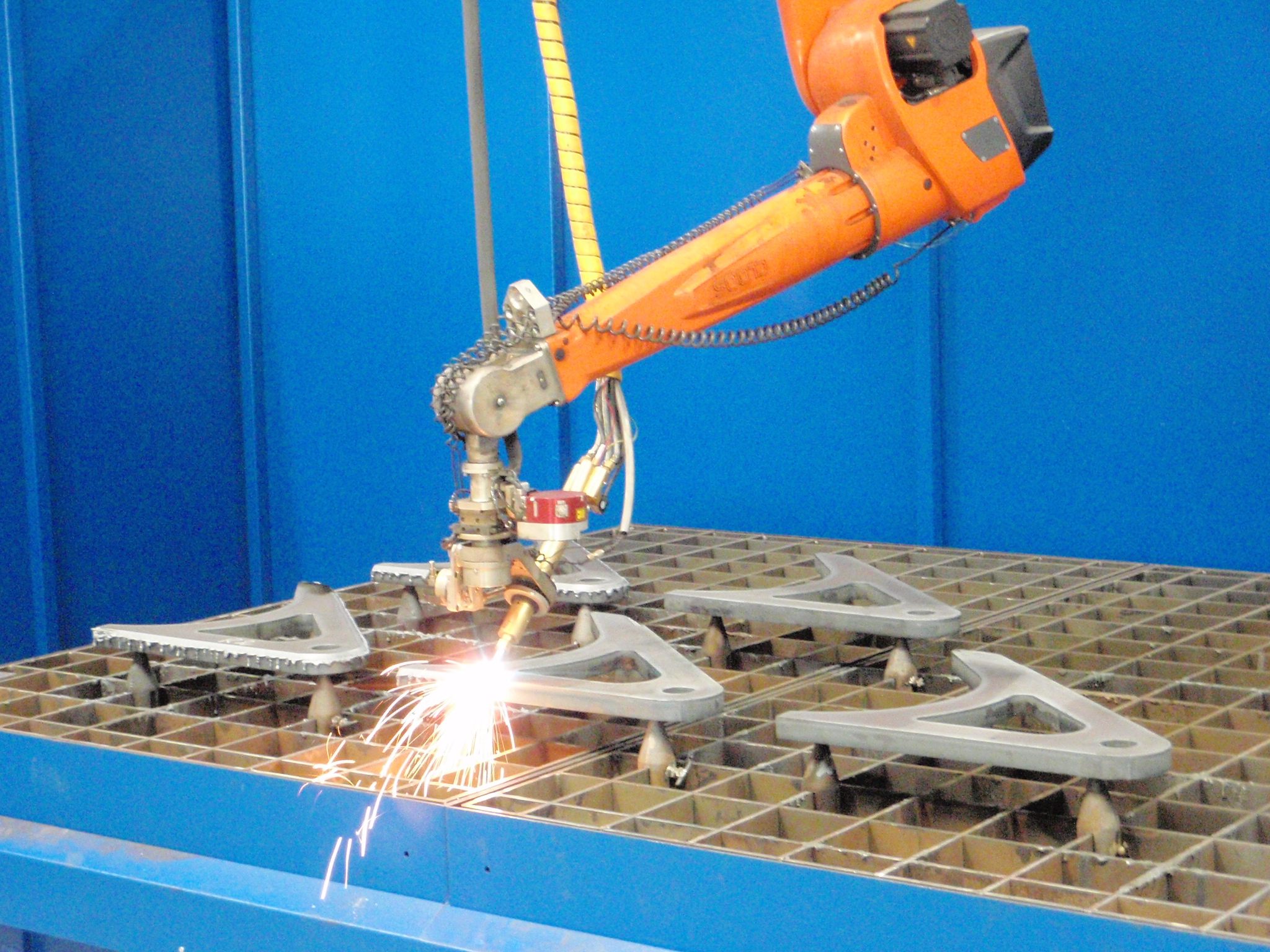

MOSES-SHEET automates the programming of high quality bevel cuts on sheet metal parts. Complex programming tasks such as weld seam preparation and the production of functional or visible surfaces are completed in the shortest possible time.

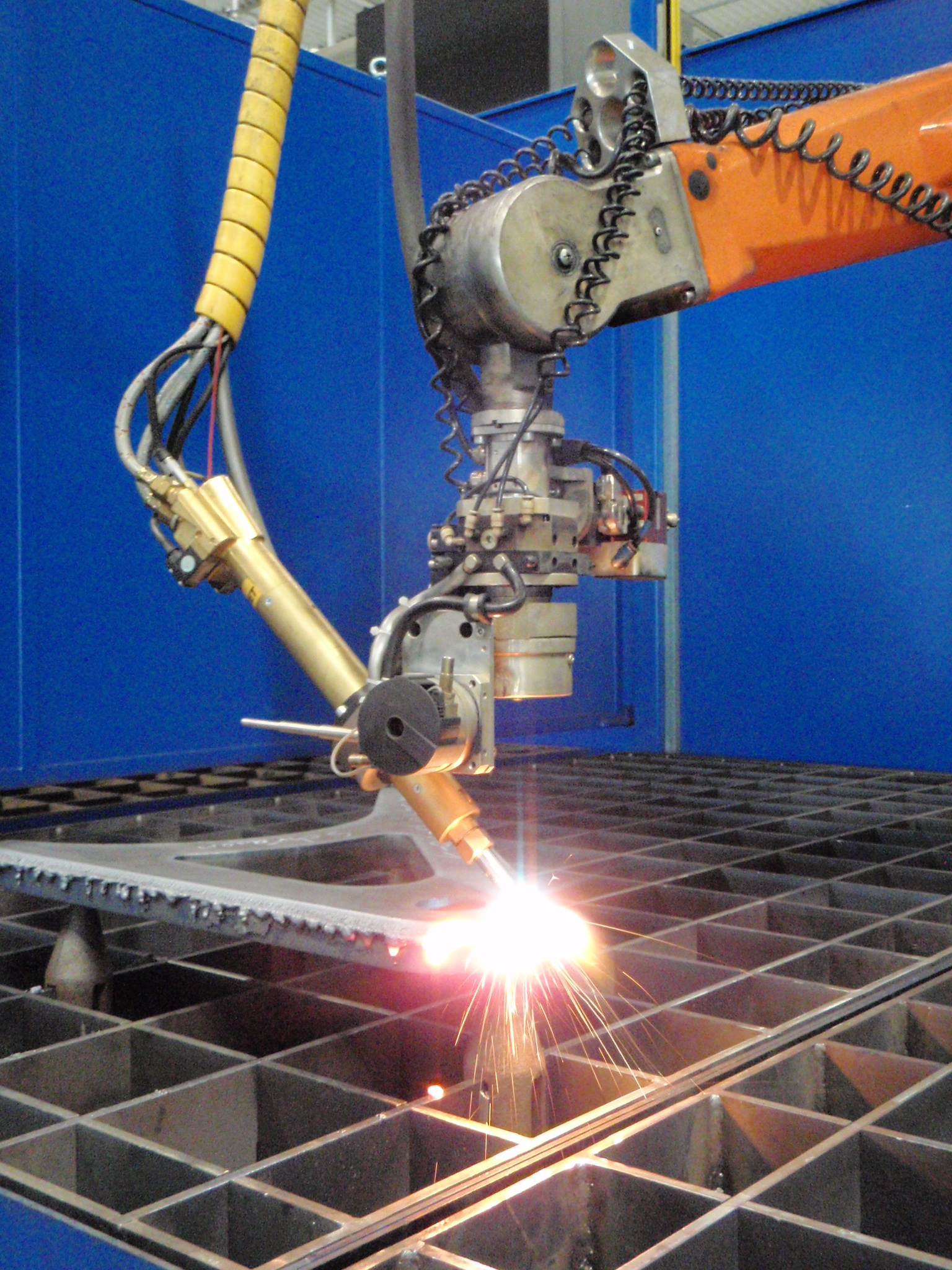

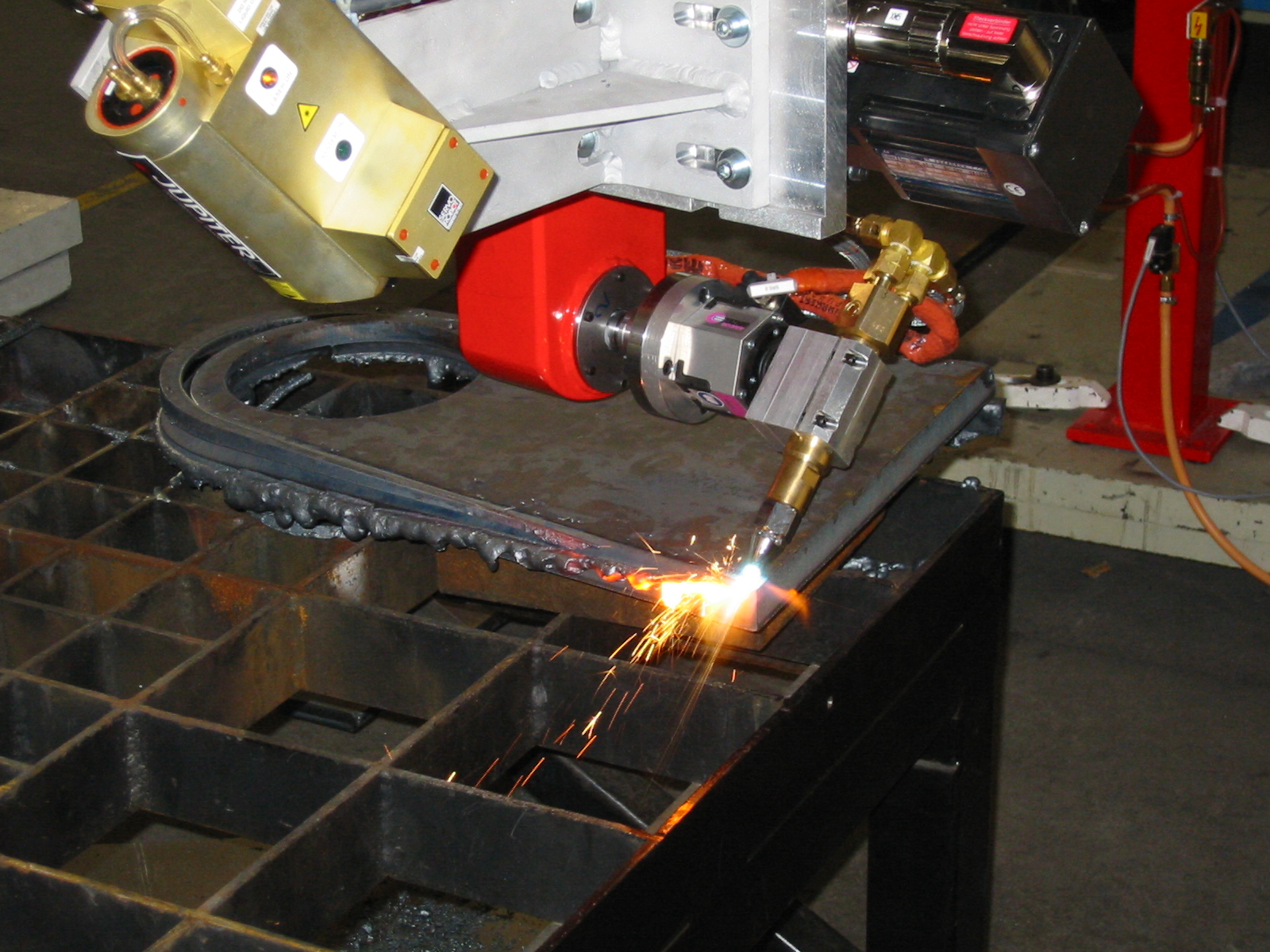

The input information for the generation of the robot programs are simple 2D CAD drawings of the components. These can be imported from any CAD system or created directly in MOSES. The selection of the edges to be machined and the input of the cutting parameters is done easily and comfortably in a few steps. The complete robot program is then generated fully automatically. The cutting speed is continuously adapted to the effective cutting depth or cutting angle. To ensure high cutting quality even at inner and outer corners of the contours, special motion strategies are applied and melting of the corner areas is prevented.

The high accuracy of the bevel geometry is achieved by adapting the robot program to the actual component position. Reference points are already generated during the CAD-based program generation, which enable the robot to precisely measure the component position. This calibration can be done fully automatically with the help of laser distance sensors or tactile pins, or semi-automatically by manually teaching the reference points. Furthermore, MOSES-SHEET offers the option to control a camera for online edge tracking during the cutting process. This sensor even compensates for the heat distortion that occurs during cutting.

With the assistance of the graphic 3D motion simulation, the collision-free executability of the motion programs and the reachability of all path points can be checked. In addition, the machining time can also be precisely predicted.

In this way, MOSES-SHEET enables the economical automation of cutting tasks with the smallest quantities up to "batch size 1" with the highest quality and simplest operation. Compared to conventional programming methods, the programming time can be reduced by up to 95%.